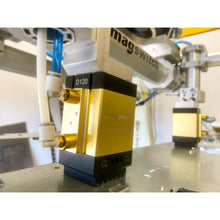

D120 A Magnetic Gripper Tool for Robotic End of Arm Tooling (EOAT) - 81401457

The D120 is an ultra shallow field, multi-array, pneumatic actuated, magnetic gripper tool designed to excel in material handling on thin sheet metal (< 2.0mm). The D120 excels where traditional magnets, EPM (Electric Permanent Magnetic) grippers, and suction cups cannot get a strong enough grip.

This exciting new industrial robot end-of-arm tooling (EOAT) is ideally suited for robotic automation processes including press loading/unloading, part de-racking, machine tending, pick and place, robotic picking, or ergonomic lift assist. The D120 outpaces the other automation solutions with standard sensing options, NAAMS standard mounting, fail-safe operation, and the highest holding force per sq mm on thin sheet metal available in today’s market.

Features

Featuring advanced NAAMS mounting interfaces, the D120 ultra shallow field magnetic gripper increases productivity and outclasses alternatives with its:

- Industry best holding power per square centimeter (3x the nearest competitor)

- Ultra shallow field technology

- Flexible mounting capabilities

- Industry best actuation times under 300ms (faster than EPM)

- Fail-Safe Operation (parts will not fall during power loss)

- Available tool ON/OFF Sensing

- A full range of standard accessories including compensation devices

- Zero energy consumption in either the ON or OFF state

- Can operate at 100% duty cycle

Competitive Benefits

- Improved hold force per square centimeter

- Delivers the most hold force in a small footprint

- Industry best de-stack capability - ultra shallow field technology enables the D120 to lift a single sheet of 2.0mm thickness from a stack of sheets

- Fewer tools are required to move a part

- Simple end-of-arm designs

- Magswitch is a world leader in magnetic single-sided gripping

Industrial Automation Applications

Automotive

In addition to the traditional applications of robotic handling of hoods, roofs, floor pans, door panels, dash panels, and roof bows; the D120 is the #1 magnetic gripper used today for high-volume automated production line handling of EV (Electric Vehicle) battery trays. Magswitch can facilitate safe and secure handling during assembly processes, reducing the risk of accidents and ensuring precise positioning.

Stamping Operations

Loading and unloading blanks and transferring parts require careful handling to maintain efficiency and safety. The Magswitch D series provides a reliable solution for these tasks, improving productivity and minimizing downtime.

White Goods Manufacturing

Material Handling of large appliance shells (washing machines, dishwashers, clothing dryers) demands robust equipment to ensure safety and efficiency. Magswitch offers a dependable solution for securely gripping and maneuvering these bulky components while streamlining production processes.

Consumer Goods Production

From grills and smokers to mowers and blowers, consumer goods consist of various components that require careful handling during automated assembly. Magswitch D series provides the stability and precision needed for these tasks, contributing to higher-quality end products and a robust manufacturing process.

Unlock unbeatable robotic automation performance with Magswitch's powerful D120 pneumatic magnetic gripper for all your automated pick and place needs.

SPECIFICATIONS

| Maximum Breakaway Force 1,2 | 1133 N |

| Maximum Shear 1,2 | 296 N |

| Thickness for De-Stack | 0.08 in/2.0 mm |

| Maximum Allowable Pressure | 116 psi / 8 Bar |

| ON Target Actuation Pressure | 60.0 psi / 4.1 Bar |

| Net Weight | 2.76 lb / 1.25 kg |

| Air Port Thread |

2xG1/8 (1/8 BSP) |

| Mounting Options |

Top - 2X NAAMS |

| Magnetic Pole Footprint | 2.13 x 1.97 in / 54.0 x 50.0 mm |

| Material Thickness – mm (in) | 0.5 (.020) |

0.6 (.025) |

0.7 (.028) |

0.8 (.031) |

0.9 (.035) |

1.0 (.039) |

1.1 (.043) |

1.2 (.047) |

1.3 (.051) |

1.4 (.055) |

1.5 (.059) |

2.0 (.079) |

3.0 (.118) |

4.0 (.157) |

5.0 (.197) |

| Maximum Force – 1,2,5 N (Newton) | 304 |

401 |

471 |

538 |

698 | 843 |

878 | 934 | 1017 | 1058 | 1094 | 1130 |

1133 |

1133 |

1133 |

| Required Air Pressure 4 – bar (psi) | 2.4 (35) |

2.8 (40) |

2.8 (40) |

3.1 (45) |

3.1 (45) |

3.1 (45) |

3.4 (50) |

3.4 (50) |

3.4 (50) |

3.4 (50) |

3.8 (55) |

4.1 (60) |

4.1 (60) |

4.1 (60) |

4.1 (60) |

- SWL (Safe Working Load) = Maximum Force5/ Safety Force (≥5)

- 1Determined in laboratory environment on 2” thick SAE1018 Steel with surface roughness 63 micro inches with optimized pole shoes. Many factors contribute to the actual breakaway force and safe working load in each application. Consult a Magswitch Applications Engineer and test the Magswitch in each application before deployment.

- 2All data applies to unit with flat pole shoes installed.

- 3Determined with SAE1018 Steel L=200mm W=200mm.

- 4Values may vary by +/- 5%.

- 5Maximum forces listed above are not safe lifting forces. Designer must take into account safety factor when specifying tool. Magswitch recommends SWL = 5:1 for most applications.

ACCESSORIES (Sold Separately)

| Product SKU | Description |

|---|---|

| 270414 | D85/D120 Sensor (TWO REQUIRED PER TOOL) |

| 88001639 | D120 Compliance Device |

| 880501 | Ball Mount, NAAMS, 28.5mm, Kit |

| 88001609 | Wear Pad |

| C230808BC | Friction Coated Wear Pad |

| C230808BD | Friction Coated Wear Pad |

Downloads

D120 Downloads:

- 81401457-D120 Spec Sheet

- 81401457-D120 STEP File

- 81401457- D120 Spec Sheet DE

- D85/D120 - Product Brochure DE

D120 Accessories Downloads:

- 270414 - D85/120 Sensor STEP File

- 88001639- D120 Compliance Device Top Mounted Spec Sheet

- 88001639- D120 Compliance Device Top Mounted STEP File

- 8800501-Ball Mount, NAAMS, 28.5mm, Kit Step File

- 88001609 - Wear Pad STEP File

- C230808BC - Friction Coated Wear Pad STEP File

- C230808BD - Friction Coated Wear Pad STEP File

Magswitch Downloads:

- Automation Catalog

- D-Series Brochure

- MAC Declaration of Incorporation – Assembly Manual ( English | Spanish | German | French)