Koike MagWheel Robotic Welding Integration

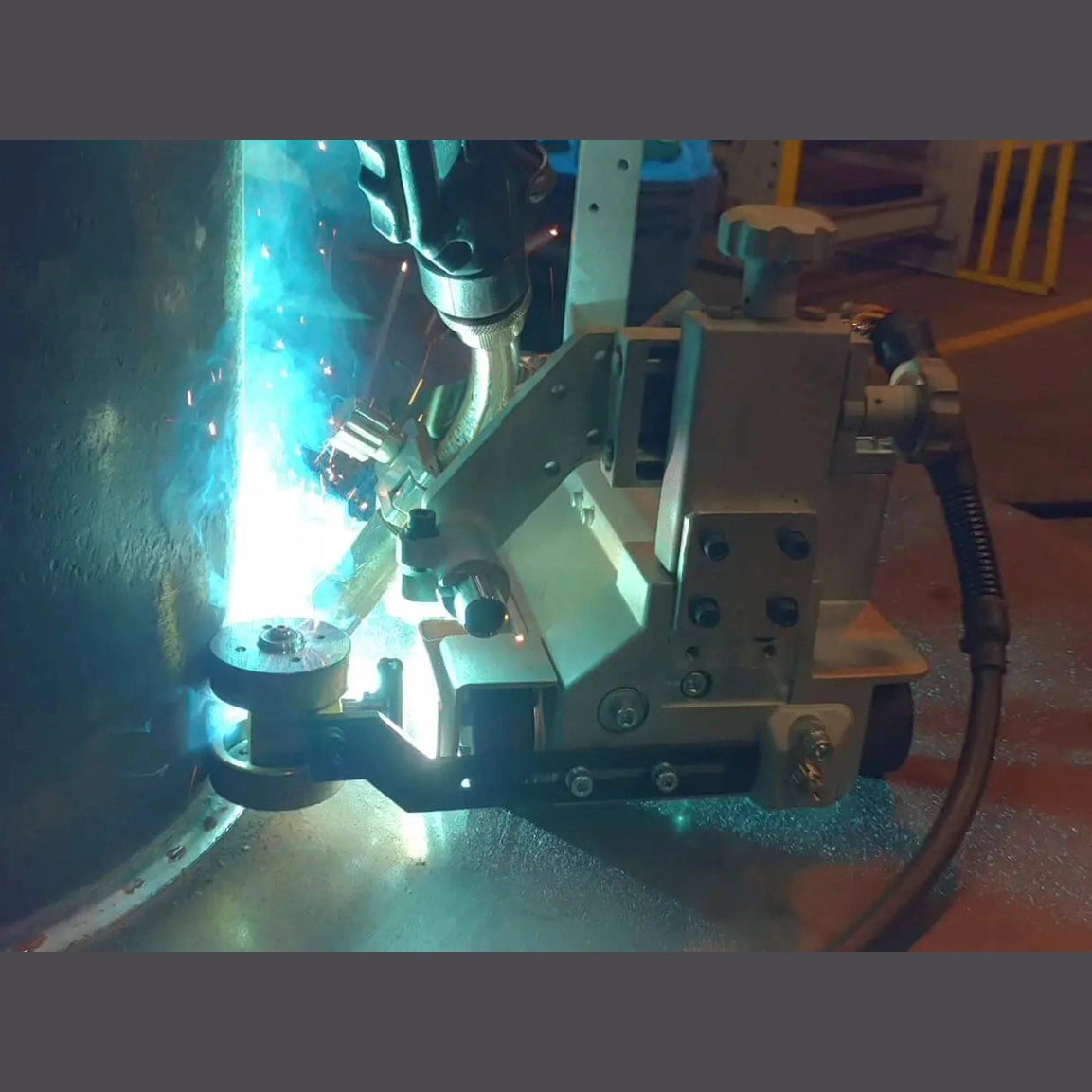

Koike Aronson are leaders in manufacturing high quality metal cutting, welding and positioning equipment. It was an integration that was meant to happen. Magswitch MagWheels are perfect for driving powerful connection on any ferrous surface enabling flat, vertical or inverse travel. About 6 years ago, this integration became a reality. Koike has been using the MagWheels for one of their automated welding systems.

Koike’s machine comes out of the box with brass guide rollers. If you are familiar with how this type of welding tractor works, they use mechanical force to hold the carriage to the work piece. They have 2 guide rollers that will set the distance form the fillett plate. One is set shorter that the other. This causes the machine to drive into the work piece and hold a consistent distance. In turn, the welding head will stay positioned in the exact same spot throughout the weld. It does not matter the length of weld. These machines can run up over 50’ in distance depending on the length of welding cable.

Koike Products

Portable welding machines assist the professional welder in maintaining a safe and high quality weld. Sometimes referred to as semi-automation, the portable welding carriages make welding easier for the welder because the torch is taken out of the welder’s hand and moved along in a controlled manner.

Magswitch Finds A Solution

One of the issues they faced with the machine however, is what to do if the fillett plate is convex in nature. A prime example is welding a piece of large diameter pipe to a structure. Since they did not have the ability to track this, they relied on the Magswitch magnetic guide rollers aka MagWheels to attach their machine to the base plate. With the MagWheels, they were able to find a problem to their solution. These products are now sold across the country in the shipbuilding and railcar industry.

MagSwitch MagWheels

MagWheels are a powerful connection for drive units on any ferrous surface enabling flat, vertical or inverse travel. Applications include positioning and guiding, sheet feeding, pipe handling, fitting and fabrication, and numerous OEM automation and fixturing applications. MagWheel results in efficiency, new applications, and productive solutions. Underneath the patented MagWheel design is the highly functional AR Housing. Through clever innovation of the original Magswitch, the MagWheel provides all the features of a standard Magswitch on the move. The magnetic flux path through the wheels means climbing, carrying, and driving anywhere above or below a ferrous surface is now a reliable, fail-safe reality.

Magswitch Custom Product Solutions

The versatility of Magswitch Technology has opened up so many applications that can be performed significantly faster and much more safely. We provide a whole range of expertise from design engineering, manufacturing and delivery to marketing and customer service. Combining our technology with Magswitch expertise, we can create specialized products that fit your needs and budget. Our Application Engineers will work with you to determine your needs in order to design, deliver and support your solution for years of reliable service.