M30 2.0 Magnetic Gripper Tool for Robotic End of Arm Tooling (EOAT) and Fixtures - 81401590

Maximize Magnetic Robotic Automation with the M30 2.0 Pneumatic Gripper

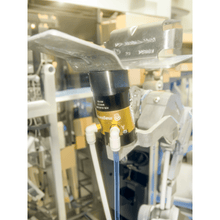

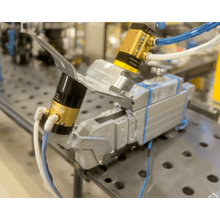

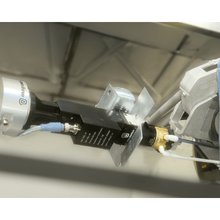

The powerful M30 2.0 magnetic gripper revolutionizes industrial robotics automation with its compact, fail-safe design. This cutting-edge pneumatic magnet boasts shallow field rare earth magnets for superior holding force, ensuring secure ferrous part transfer without slipping or shifting, even with contaminated (oily or fluid-coated) materials. Ideal for robotic automated systems including pick and place, end of arm tooling (EOAT), material handling in automotive Body-in-White (BIW), press transfers, part flipping stations, and collaborative robot (COBOT) applications.

Industrial Automation Applications

- Pick and Place

- Robot Arm End of Arm Tooling (EOAT)

- Collaborative Robot (COBOT)

- Automotive Industry Body-in-White (BIW) Material Handling

- Machine Tending

- Bin Picking

- Press Transfers

- Part Flipping Stations

The M30 automation tool features advanced NAAMS standard mounting and G-threaded mounting interfaces. The M30 2.0 magnetic end effector outclasses traditional alternatives with its unparalleled holding power per square mm, durable steel housing for maximum longevity, flexible mounting capabilities, and actuation times under 400ms.

Features

- Flexible Mounting: NAAMS and G-Threaded Interfaces

- Durable Steel Housing

- Actuation Times < 400ms

- Fail-Safe Operation

Benefits

- Streamlined Production Lines

- Increased Quality Control

- Reduce Operational Costs

Elevate your manufacturing production processes with Magswitch's innovative single-sided part-holding automated solution. Ideal for automated processes like sealing, gluing, laser welding, or laser cutting, our magnetic grippers enable world-class automation.

Eliminate clamp chatter and enhance product quality while reducing compressed air consumption by up to 90%. Streamline your operations and boost productivity by shortening takt time by 20%. Magswitch's high-performance magnetic grippers empower you to achieve unparalleled efficiency and cost-effectiveness in your automated manufacturing processes.

NOTE: ON/OFF sensing is NOT available with the M30 2.0

SPECIFICATIONS

|

Maximum Breakaway Force 1 |

729 N |

|

|

Maximum Shear Force 1 |

157 N |

|

|

Thickness for De-Stack2 |

0.157 in |

4 mm |

|

Maximum Allowable Pressure |

145 psi |

10.0 Bar |

|

On Target Actuation Pressure |

28 psi |

1.9 Bar |

|

Air Port Threads |

2x G1/8 |

|

|

Net Weight |

1.03 lb |

0.47 kg |

|

Individual Magnetic Pole Footprint |

1.65" x 1.23" |

42mm x 31.2mm |

|

Mounting Options |

1x Top (With 3/8 NPT Mounting Option): 3/8 - 18 NPT 1x Top (With NAAMS Mounting Option): Ø6-M8-Ø6 |

|

|

Material Thickness - mm (in) |

0.5 |

0.6 |

0.8 |

1.0 |

2.0 |

3.0 |

4.0 |

5.0 |

6.0 |

|

(0.020) |

(0.024) |

(0.031) |

(0.039) |

(0.079) |

(0.118) |

(0.157) |

(0.197) |

(0.236) |

|

|

Maximum Force 1 - Newton (N) |

71 |

83 |

129 |

219 |

437 |

645 |

710 |

729 |

729 |

|

Required Air Pressure 3 - Bar (psi) |

4.1 |

3.8 (55) |

3.4 (50) |

3.1 (45) |

2.2 (32) |

1.9 (28) |

1.9 (28) |

1.9 (28) |

1.9 (28) |

-

1 Determined in laboratory environment on 2” thick SAE1018 Steel with surface roughness 63 micro inches . Many factors contribute to the actual breakaway force and safe working load in each application. Consult a Magswitch Applications Engineer and test the Magswitch in each application before deployment.

2 Tested and Determined with Two SAE1018 Steel Sheets L=200mm W=200mm Thickness=4 mm.

3 Values may vary by +/- 5%.

4 Maximum forces listed above are not safe lifting forces. Designer must take into account safety factor when specifying tool. Magswitch recommends SWL = 5:1 for most applications.

Downloads

M30 2.0 Downloads:

Magswitch Downloads:

- Automation Catalog

- MAC Declaration of Incorporation – Assembly Manual ( English | Spanish | German | French)